Introduction:

This machine is a PLC controlled metallographic sample cutting machine, and it can also be controlled by electronic handwheel. The structure of the machine is firm and reasonable. The frequency conversion motor is directly connected with the cut-off wheel, which provides power transmission between the motor and the cut-off wheel and ensures the cutting efficiency. Also it adopts electromechanical separation structure to effectively protect electrical safety, which has convenient maintenance and long service life. Using Schneider electric and Mitsubishi software, X, Y, Z axis can be automatically and accurately controlled, it can adjust the amount of feed according to the hardness of material to achieve the fastest cutting effect. The cutting speed is controlled by frequency conversion, which has very high reliability and control ability.

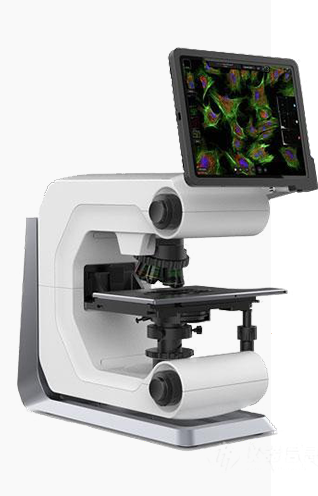

This machine is specially designed for large-capacity cutting of large workpieces, making it easier to maintain machine parts and deal with large workpieces. The double-opening structure of sliding door and hinged door can more conveniently load large workpieces in the appropriate position, and the workpieces can be sent into the cutting chamber from the top, front and left directions. The cutting chamber adopts fully enclosed structure and the safety lock is closed when cutting, which is safe and reliable. Equipped with explosion-proof transparent observation window, powerful exhaust fan and double LED lighting, it makes the observation clearer. Cursor positioning makes cutting more accurate and 10 inch touch screen display and control makes cutting easier. With the mobile magnetic circulating cooling water tank, the surface of the sample after cutting is bright and flat without burns, thus it is the ideal equipment for large sample cutting. It is especially suitable for cutting large workpieces in iron and steel metallurgy, automobile shipbuilding, heavy machine processing, bearing manufacturing and other industries to prepare non-burn samples.

Features:

1.With ABB spindle motor (except QGZ-100), Schneider electric, and Mitsubishi software, these core components guarantee the quality.

2.X, Y, Z axis can be automatically and accurately controlled or manually electronic handwheel control.

3.It has continuous cutting and pulse cutting two modes which can adjust the amount of feed according to the hardness of material to achieve the fastest cutting effect.

4.With two LED lamps and automatic exhaust system, it can increase the brightness and clarity of the cutting chamber.

5.Cursor positioning function makes the sample cutting location more accurate.

6.The mobile magnetic circulating cooling water tank has effective filtration and can prevent sample burns.

7.It has large cutting space and can feed cutting in multi-direction.

8.The cutting door is completely closed when working, which is safe and reliable.

Application range:

It is suitable for various ferrous metals, non-ferrous metals, heat treatment parts, forgings, semiconductors, crystals, ceramics and rocks etc.

Technical Parameters:

| Model | QGZ-100 | QGZ-120 | QGZ-200 | QGZ-300 |

| Control Method | Manual/Automatic, Three-axis Linkage, 10 inch Industrial Touch Screen Control or Electronic Handwheel Control | |||

| Features | Schneider Electric, Mitsubishi Software, Automatic Exhaust System, Alarm System, Double LED Lighting, Cursor Positioning | |||

| Feeding Speed | 1~200mm/min(Suggest 5~12mm/min) | |||

| Cut-off Wheel | Φ350×2.5×Φ32 mm | Φ380×2.8×Φ32 mm | Φ400×3×Φ32 mm | Φ400×3×Φ32 mm |

| Cutting Table

(X*Y) |

With X axis: 410×350 mm

No X axis: 510×350 mm |

450×350 mm | 485×400 mm | 530×630 mm |

| Y Axis Travel | 250 mm | 250 mm | 300 mm | 420 mm |

| X Axis Travel | With X axis: 140 mm | 100 mm | 100 mm | 110 mm |

| Z Axis Travel | 160mm | 200 mm | 230 mm | 230 mm |

| Max. Cutting Capacity | 100×100 mm | 120×120 mm | 200×150 mm | 300×150 mm |

| Clamp Opening | 100 mm | 120 mm | 200mm | 300 mm |

| Spindle Motor | Frequency conversion motor, 4kW | ABBfrequency conversion motor, 5.5kW | ABBfrequency conversion motor, 7.5kW | ABBfrequency conversion motor, 7.5kW |

| Spindle Speed | 500-2800 r/min | |||

| Feeding Motor | Stepper motor | Servo motor | ||

| Power Supply | 380V,50Hz, 20A

Three-phase five-wire |

380V,50Hz, 30A

Three-phase five-wire |

||

| Dimensions | 1200×1100×1800mm | 1450×1000× 1850mm | 1550×1100× 1900mm | 1650×1350× 1900mm |

| Net Weight | 1700kg | 1800kg | 2200kg | 2500kg |

| Water Tank Capacity | 80L | 120L | ||

| Pump Flow | 50L/min | 100L/min | ||

| Water Tank Dimensions | 610×550×680mm | 700×630×800mm | ||

| Water Tank Weight | 85kg | 90kg | ||

Packing List:

| Name | Specification | Qty |

| Machine Body | 1 set | |

| Water Tank | 1 set | |

| Cut-off Wheel | 2 pcs | |

| Cutting Fluid | 3kg | 2 bottles |

| Spanner | 2 pcs | |

| Inner Hexagon Spanner | 5mm,6mm | each 1 pc |

| Socket Spanner | 24mm | 1 pc |

| Water Inlet Pipe | 1 pc | |

| Water Outlet Pipe | 1 pc | |

| Usage Instruction Manual | 1 copy |

评价

目前还没有评价