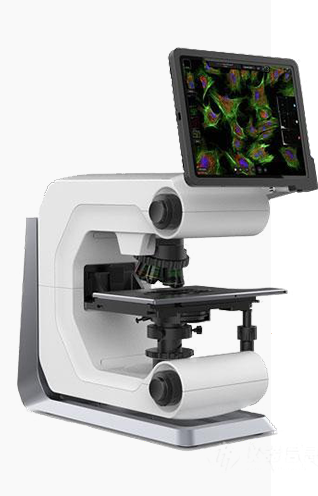

300/310HRSS-150 Automatic full Rockwell hardness tester

Closed loop control of test force;

automatic tracking measurement, measurement error caused by frame deformation and workpiece deformation;

automatic clamping of workpiece, without manual application of initial test force, can measure special-shaped parts;

high precision grating displacement measurement system;

LCD, menu operation, complete functions (data processing, hardness conversion, etc.);

RS232 data interface;

optional upper computer and proprietary software;

the accuracy shall comply with GB/T230.2 ISO6508-2 and ASTME18.

Application:

Determine the surface Rockwell hardness of ferrous metals, alloy steels, cemented carbides and metal surface treatments, such as carburization, nitridation and electrodeposited coatings;

It is especially suitable for precise measurement of parallel plane and anisotropic workpiece.

Main technical parameters:

Measuring range: Rockwell: 20-88hra, 20-100hrb, 20-70hrc

588.4, 980.7, 1471 Newton (60, 100, 150 KGF)

Surface Rockwell: 70-91hr15n, 42-80hr30n, 20-70hr45n, 73-93hr15t, 43-82hr30t, 12-72hr45t

147.1, 294.2, 441.3 n (15, 30, 45 KGF)

Test force: Rockwell: 588.4, 980.7, 1471 Newton (60, 100, 150 KGF)

Surface Rockwell: 147.1-294.2-441.3n (15-30-45kgf)

Test items: Rockwell HRA, B, C, D, N, t scales (E, F, G, h, K optional)

Reading resolution: 0.1hr

Movement range of probe: 50mm

Movement range of side head: 50mm

Output: Built in RS232 interface

Allowable * * height of sample: 170 mm

Distance from RAM center to machine wall: 150 mm

Reading resolution: 0.1HR

Overall dimensions: 910×535×220mm

Weight: About 85 kg

Power Supply: AC220V ,50/60HZ

Standard configuration:

Small flat test bench: 1 V-shaped test bench: 1

Diamond cone indenter: 120 ° 1 Steel ball indenter: 1/16’1

Standard Rockwell hardness block: 5 pieces Standard surface Rockwell hardness block: 4 pieces

printer: 1

评价

目前还没有评价