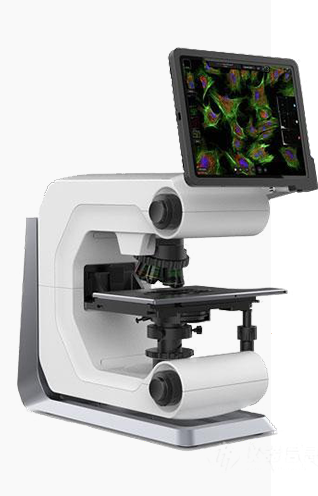

D5500 semi automatic paraffin section machine

Features: (the blue part can be marked on the whole machine)

The machine adopts humanized design, compact structure, convenient and fast slice and patch exchange, and can complete slice and patch conversion by shaking the hand wheel with one hand (perception mode: half circle is patch state, patch is half circle fast operation; whole circle is slice state, slice is flexible fine trimming)

The drive feed system is controlled by intelligent program, including conventional slicing mode, intelligent perception slicing mode and full layer slicing mode

Full layer slice mode: it can prompt to take the slice according to the setting of different faults, and the slice analysis is like the function of tomography.

Import drive system, with intelligent perception chip repair, slicing function, fast forward, fast backward, conversion function, with sample automatic retraction function, fine trimming chip function

Adopt the international advanced screw motion system to ensure the matching accuracy and better slicing effect

It has two positioning memory functions. The user can position the sample when trimming the sample. After positioning, after loading the sample each time, press the memory key to return to the sample positioning point. Memory 1 and memory 2 can simultaneously memorize the location samples of patch and slice.

OLED module is used as the display screen, with clear handwriting, no backlight, 3600 angle can clearly observe the display data, no blind spot

Coding small hand wheel control system is convenient for users to carry out electromechanical simulation control with the speed of rotation. It also has safety alarm system, drive overload protection, and automatic sleep protection system.

Special positioning head system, with red vertex marked as 0 degree positioning. X / y axial adjustment is fast and accurate, and interchangeable sample chuck (wax block chuck and embedding box chuck are optional) is configured.

Adopt imported advanced cross roller guide rail, free of lubrication and maintenance, ensure the slide and accuracy of slice

The tool holder can be adjusted by lateral movement without moving the blade by hand. The blade can be used in its full length (with three positioning points to maximize the utilization rate of the cutting edge); the tool holder base is equipped with a scale mark to facilitate accurate positioning of the tool holder and make the tool setting distance of the sample intuitive.

The blade holder is equipped with a knife guard to cover the full length of the blade, which can protect the user safely, and has a knife push bar to facilitate the replacement of the blade

The handwheel balance fine adjustment system can be positioned at any position and locked to ensure the safety and convenience of the slicing process. The sample upper locking function is suitable for the user to replace the sample safely.

Easy to disassemble waste trough, top groove design of cover, can store brush, tweezers, disposable blade and other tools, equipped with soft silicone anti-skid pad to prevent tools from sliding out. When cleaning the instrument, it is more convenient to take out and clean.

The front and back bottom of the instrument are equipped with humanized handle slots, which are convenient for users to install, carry or move the instrument

technical parameter

The range of slice thickness is 0.25-100 μ M

0.25-2.5 μ m increment 0.25 μ M

2.5-5 μ m increment 0.5 μ M

5.0-10 μ m increment 1 μ M

10-30 μ m increment 2 μ M

30-60 μ m increment 5 μ M

60-100 μ m increment 10 μ M

The range of film thickness is 1-600 μ M

1-10 μ m increment 1 μ M

10-20 μ m increment 2 μ M

20-50 μ m increment 5 μ M

50-150 μ m increment 10 μ M

150-600 μ m in increments of 50 μ M

Retraction range: 0-100 μ M

Close to 0 retract

0-5-10-15 ——– 100 adjustable

Fault interval span: 10-6000 μ M

10-12-15-20-25——5000–6000μm

Horizontal feed: 30mm

Vertical movement: 70mm

The moving range of blade pressing plate is about 20 mm

Sample positioning: 8 ° horizontally; 8 ° vertically

Sample holder can rotate 360 degrees (optional)

Minimum division value of slice adjustment: 0.25 μ M

Maximum paraffin section area: 70 × 70mm

Feeding speed: 0um ~ 5000um / S

Accuracy of slice: ± 1%

Power supply voltage: AC110V / AC 220V

Frequency: 50 Hz / 60 Hz

Power: 100VA

Overall size: 595x 465x 295mm

Total net weight: 28KG

评价

目前还没有评价