FEATURES

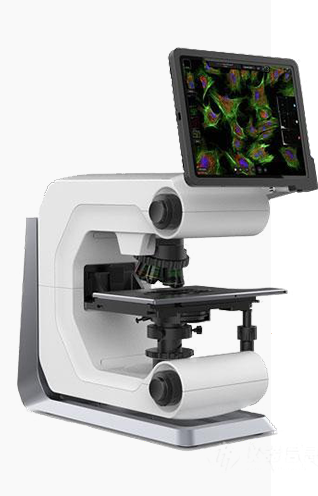

High resolution electro-optical system

New generation of low aberration objective lens; Deceleration sample stage; High-resolution imaging at low voltage

Efficient and convenient user experience

New user interface design; Extensive software measurement functions; Optical navigation;Beam current measurement

High performance signal detection system

Low noise Inlens detector; Automatic retractable backscatter detector; Extensive detector extension interface.

FUNCTIONS

Secondary electron detector

High signal-to-noise ratio, high bandwidth

Extended depth of field to characterize the morphology and structure of the sample surface

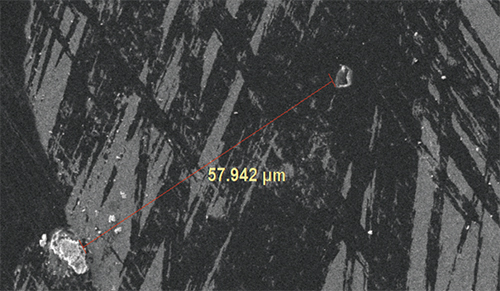

Dimension measurement

With extensive image measurement functions such as distance, angle, horizontal/vertical line, etc

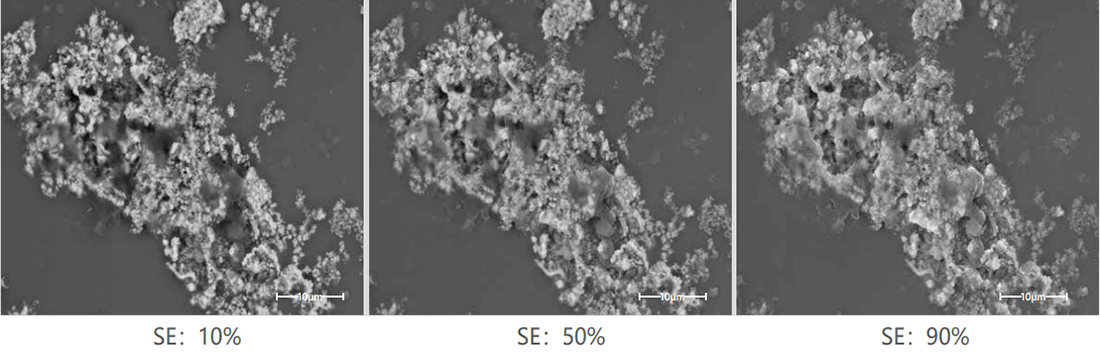

Simultaneous imaging with different detectors

Dual-channel images display of SE and BSESignal mixing ratio of different detectors can be set freely

BSE detector, to detect the composition characterstics of the sample surface

Large image stitching

Continuous automatic image collection

Accurate stitching of multiple images to generate large and high-resolution images

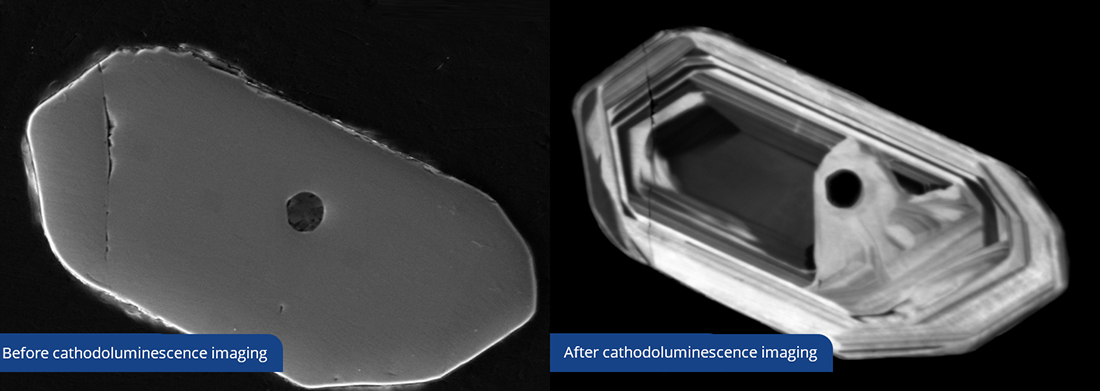

Cathodoluminescence imaging

High signal-to-noise ratio, high band width extended depth of field to characterize the morphology and structure of the sample surface

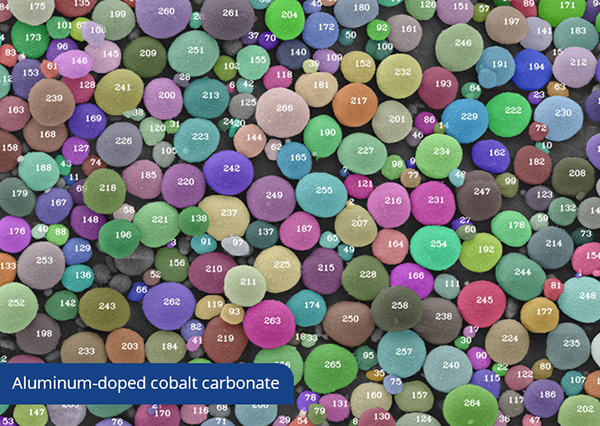

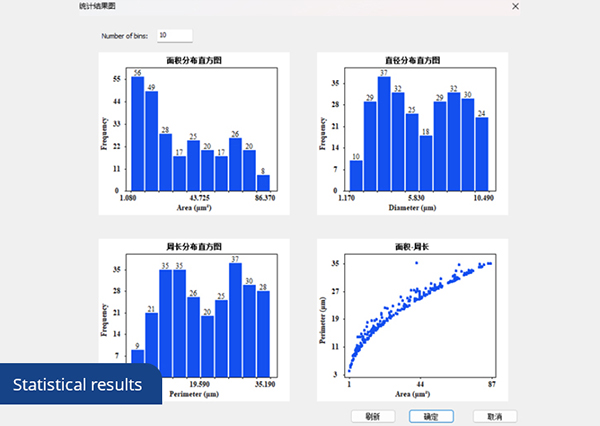

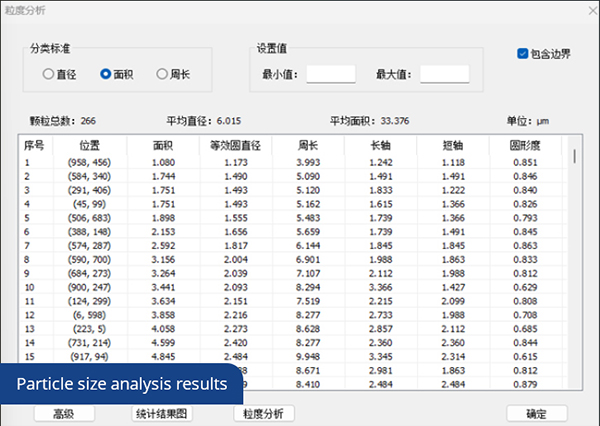

Particle size analysis

The composite image processing algorithm of deep learning is adopted to automatically identify the proportional scale, accurately identify the particles in the image, and count and export various morphological parameters for more comprehensive particle size and particle shape statistics. (Aluminum-doped cobalt carbonate; Silicon dioxide; Statistical results; Particle size analysis results.

Customization

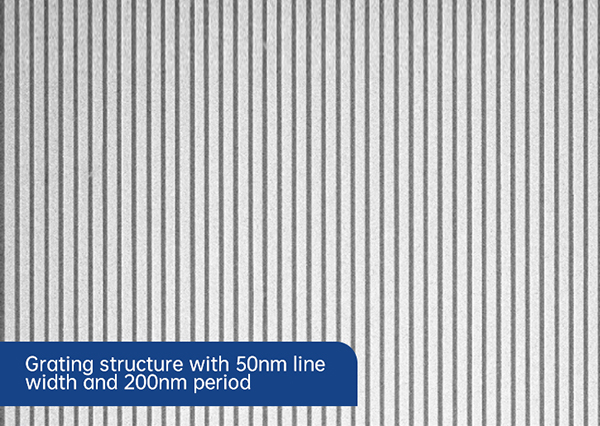

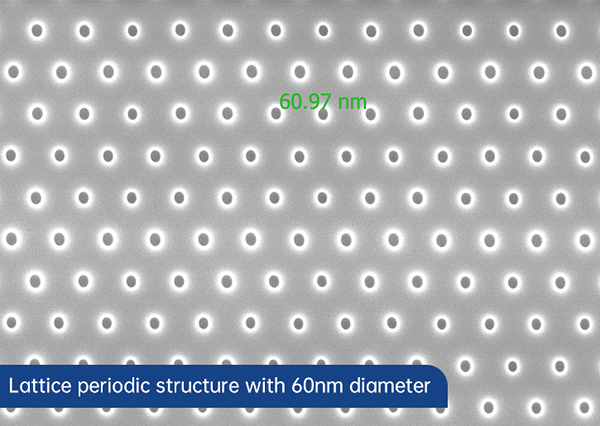

Electron Beam Lithography (EBL)

Functions: The SEM-based electron beam lithography (EBL) system allows precise control of the scanning path and energy deposition of the electron beam to realize high-resolution patterning exposure. The system adopts advanced electron beam scanning control technology, which supports flexible and diverse pattern design and precise control. In addition to the electron beam exposure function, it also retains the original observation function of the SEM, which allows users to complete the observation and processing of samples on the same equipment, improving work efficiency and convenience.

Minimum beam spot better than 5nm; Probe current: 1pA~20nA; Line width better than 15nm

Application Scenarios: Scientific research and teaching; Microelectronics manufacturing; Prototype device development; Nanomaterials preparation; Biomedical research

Processing of 2D periodic array structure

Processing of nano-optical components and microelectronic devices

Vacuum Interconnection

*The vacuum interconnected scanning electron microscope is used for automatic detection of the products transferred by the sample cart, analyze the surface grain morphology, size, distribution and other information, and evaluate the quality of the film.

*The vacuum interconnection system allows the sample to be pre-processed under vacuum and transferred to the scanning electron microscope for observation.

*The automatic detection and feedback system monitors and records sample labels, position status, and sample handover, observing the sample transfer status by CCD or glass window.

Laser Coupling – Ultrafast Electron Microscope

*The ultrafast electron microscope uses external stimuli such as a laser or electric field to bring the sample to an excited state. Another laser beam with adjustable time delay is applied to the electron microscope filament to generate a pulsed electron beam that irradiates the sample surface, and then collects the secondary electrons escaping from the surface to characterize the excitation transient.

ACCESSORY

EDS-Energy dispersive spectrometer

EBSD-Electron back scattered diffraction

CL-Cathodoluminescence detector

STEM-Scanning transmission electron microscope

Transition chamber

Heating stage

Cooling heading stage

Tensile stage

Specifications

| Item | MIC-EM8200 |

| High vacuum resolution | 0.8nm@15kV 1.5nm@1kV |

| Magnification | 1x-3,000,000x

optical magnification 1x-100x |

| Electron gun | Schottky Field Emission Gun |

| Acceleration Voltage | 0.2kV-30kV |

| Vacuum system | 1 Sputter lon Pumps, 1 Getter Ion Combined Pump, 1 Turbo Molecular Pump, 1 Mechanical Pump |

| Detector configurations | High vacuum secondary electron detector |

| Four segmentation retractable Back scatter Detector | |

| Infrared CCD detector | |

| Inlens Detector | |

| Optical navigation | |

| Sample stage | Five axis automatic large sample stage |

| X=150mm | |

| Y=150mm | |

| Z=65mm | |

| T=﹣10°~+90° | |

| R=360° | |

| Sample specification | Maximum sample diameter:φ320mm |

| Maximum sample height: 90mm | |

| Optional accessory | EDS/EBSD/STEM/CL/Load lock transition chamber heating stage/Cooling stage/Tensile stage and etc. |

※ means optional

Application

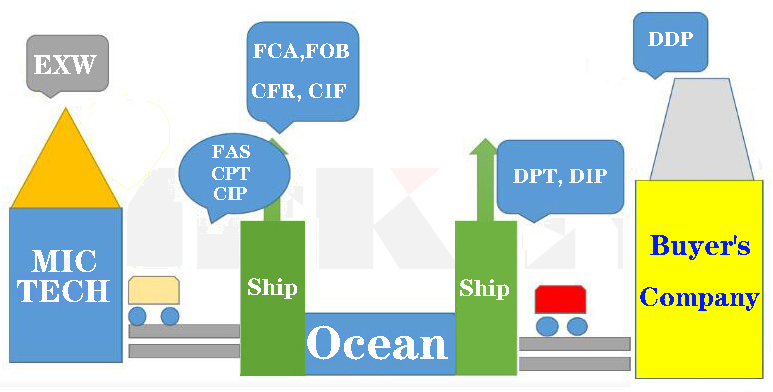

Provide customized solutions

Provide you with professional non-standard customized services to meet various application scenarios.

评价

目前还没有评价