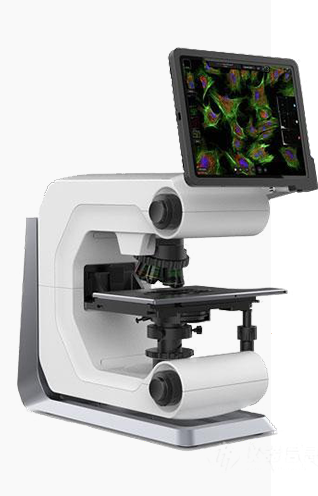

SCR-150SSZ automatic double Rockwell hardness tester

Closed loop control of test force; High precision grating displacement measurement system; Large worktable, which can measure special-shaped parts and heavy shaped parts; The first measurement is effective; Automatic tracking measurement, measurement error caused by frame deformation and workpiece deformation; The measuring head can move up and down automatically and clamp the workpiece automatically. There is no need to apply the initial test force manually. The LCD has menu operation and complete functions (data processing, hardness conversion, etc.); RS232 data interface; Optional upper computer and special software.

Technical parameters:

Reading method: Large screen direct digital display

Test force: Initial test force: 3kg (29.42n) 10kgf (98.07)

Test force: (15kg) 147.1 (30kg) 294.2 (45kg) 441.3 60kgf (588n) 100kgf (980n), 150kgf (1471n);

Loading method:Fully automatic loading, load maintaining and unloading program control

Guarantee time:2–60

Hardness measurement range:20-88HRA,20-100HRB,20-70HRC (70~94)HR15N (42~86)HR30N

(20~77)HR45N (67~93)HR15T(29~82)HR30T(10~72)HR45T

Hardness resolution: 0.1HR

Convert ruler: Surface Rockwell, Brinell, Vickers, etc

Maximum height of test piece: 300mm

Indenter center to machine wall: 150mm

Executive standard (or reference): Executive standard: gb/t230.1, gb/t230.2, jjg112 verification regulation

Power Supply: 220 VAC, 50/60 Hz

Dimensions: 1000×600×450

Gross weight: 125kg

Standard configuration:

Instrument host: 1 set small flat test bench: 1

Surface Rockwell hardness block: 3 pieces V-shaped test bench: 1

Diamond cone indenter: 1 1/16 steel ball indenter: 1

Standard Rockwell hardness block: 5 pieces printer: 1

data line: 1 piece Fuse: 2

Power cord, auxiliary tools: 1 set

评价

目前还没有评价