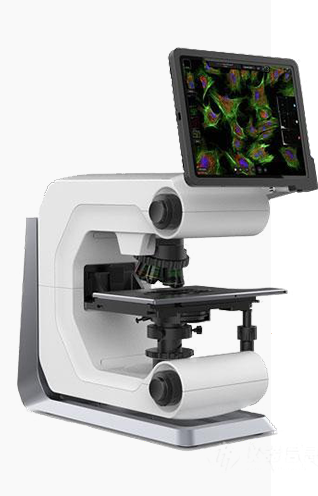

HBMW-3000C GATE TYPE BRINELL HARDNESS TESTER

Mainly feature:

* Body and table is precision casting process ,rigid, precise, reliable and durable;

* Door frame, a large movable table, the maximum moving distance is 1000mm (adjustable according to actual condition);

* Testing agencies use spoke pressure sensors, PLC anti-interference controller;

* Imported servo motor, high precision ball screws and linear guides;

* Test force, load saturation time, feed rate, the test speed can be artificially adjusted to control;

* Electronic afterburner, automatic testing process, no human operating error, optional CCD image processing system, especially suitable for hardness testing of heavy metal workpiece.

* Precision conforms to GB/T 231.2,ISO 6506-2 and ASTM E10.

Application and scope:

* It is suitable to determine the Brinell hardness of ferrous metals, nonferrous metals and alloys bearing;

* It is especially suitable for hardness testing of heavy metal workpiece.

Standard accessories:

1.Large flat anvil:1pc

2.Tungsten carbide ball penetrator: Φ5、Φ10,1pc.each;

3.Brinell standardized block:2pces;

4.20X readout microscope:1 pc.

Specifications

Measuring rang: 32-650HBW

Test force: 7355.3、9807、29421N(750、1000、3000kgf)

Max height of test piece: 950mm (adjustable according to actual condition)

Distance betwween two vertical columns: 1350mm (adjustable according to actual condition)

Max.moving distance of main shaft in cross direction: 500mm (adjustable according to actual condition)

Dimensions of worktable: 1500*1000mm (adjustable according to actual condition)

Dimensions: main machine 2000*1800*2180mm (adjustable according to actual condition)

Power supply: 380V,50/60Hz

Weight: main machine 2500KG

评价

目前还没有评价