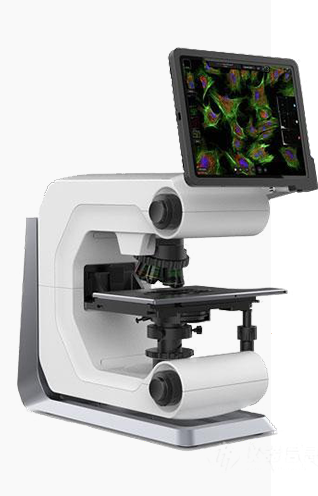

MHB-3000 Digital Brinell hardness tester

The machine adopts the current new full-automatic closed-loop sensor control technology. The stepless servo motor directly drives the ball screw to apply force, and the force value sensor feedback the force application process and size to micro classification, so as to eliminate the over loading or less loading fluctuation caused by the hydraulic or motor deceleration error or the spindle knife edge friction with the increase of the use time of the traditional weight lever amplification loading system. The system has overload and over position automatic protection function, 10 level test force selection and 14 level test scale; Solid structure, good rigidity, precision, reliability, durability and high testing efficiency; The test process is automated, and no one is responsible for the operation error; Large LCD screen, intelligent menu prompt, easy to operate; High precision reading microscope measuring system; Optional automatic indentation measurement system;

Main technical specifications:

Test force:

612.9、980.7、1225.9、1838.8、2451.8、4903.5、7355.3、9807、14710.5、29421N

(62.5、100、125、187.5、250、500、750、1000、1500、3000kgf)

Measuring range: 8-450HBS,8-650HBW

Test work piece large depth: 150mm

Test work piece large height: 280mm

Hardness reading: Digital display

Micrometer drum small value: 1.25μm

Guarantee time: 0~60s

Power Supply: 220V 50HZ

Host weight: Gross weight 150kg

Overall dimensions: 570 x330 x 910 mm (L x W x H)

Standard configuration:

Instrument host: 1 set Φ 2.5、 Φ 5、 Φ 10mm cemented carbide ball indenter: 1 each

Standard Brinell hardness block: 3 pieces Φ 110 large flat test bench: 1

bolt driver: 1 Φ 60 small flat test bench: 1

20x micrometer eyepiece: 1 Φ 60V type test bench: 2 pieces

power cord: 1 piece dust cover:

评价

目前还没有评价